In a remote corner of the Cornell Engineering Quad, the Cornell Computational Synthetics Lab blips and bleeps with activity. An Xbox 360 with Rock Band drums sits gathering dust off to the side as students mill around with machine parts, and Lego-sized plastic pieces sit in a tub on a shelf alongside failed cookie experiments. In the middle of it all, first-year graduate student Jeffrey Lipton is giving a whole new meaning to “printer jam.”

“We’ve printed peanut butter, jam — hummus was really good,” Lipton said. “Cookies are my favorite.”

3-D food printer makes dessert (Video)

Lipton is part of a team of graduate and undergraduate students working on the FAB@Home Project, an open-source collaboration research project using a 3-D printer to print everything from edible hors d’oeuvre to synthetic human organs like lungs and ears, which only recently printed.

As Lipton flips on the machine, the printer whirs to life. The machine looks a little different than a desktop ink-jet b

ut works similarly. The machine works with synthetics, or recipe ingredients, rather than ink, which fill the inkjets.

To make a cookie, users take the ingredients and load them into the printer, inserting the chemicals which make up the “batter” into the ink jets. A plastic sheet is placed at the bottom so it has something on which to “print.” The printer layers that material on top of itself, as if icing a cake. After a few layers of cookie material, users then load icing material into the ink jets to layer on top of the cookie. The whole process takes about 20 to 30 minutes and results in a product similar in size and shape to a normal cookie.

The same process is used with different “ink” materials to layer chocolate into candy or synthetic materials into molds and machine parts.

“This is actually old technology,” Lipton said. “3-D printing in general has been around since the 1980s, so there’s nothing really novel in the technology except for its price point and accessibility.”

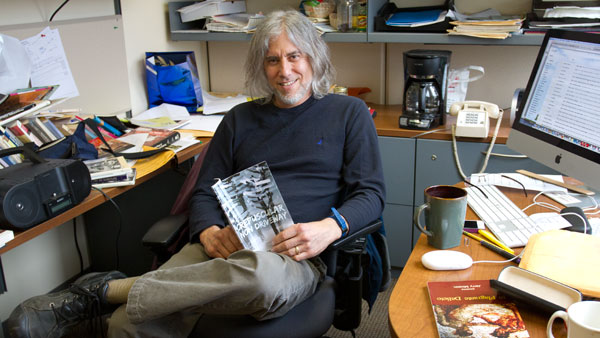

Hod Lipson, associate professor of mechanical and aerospace engineering at Cornell, has been working on the project since 2005. He said in the past, the technology has been used to primarily print machine parts, but the multi-ingredient nature of food recently created an interesting and more challenging use for the printer.

“Food is a really exciting area where you want to work with multiple materials,” Lipson said. “The ability to fabricate complicated foods by printing is exciting to many people. It’s also disarming. It’s people taking these machines that make robots and making something you have in your kitchen.”

Lipton said while working to make food on the printer has always been exciting, sometimes getting certain foods to feel and taste like they should has been difficult.

“When we did the hydrogels, that did go horribly wrong at some points,” he said. “We were trying to get texture right, so we kind of ignored flavor. So as a result, things that were supposed to feel like banana did, but they tasted like snot.”

Maor Schaal, an engineer, started working on the project with his daughter for her science fair project in 2007 at DuPont Manual High School in Louisville, Ky. He heard Cornell was working on the project and joined them in their research. He said he started with chocolate, which is one of the more difficult materials to work with.

“Chocolate is a very tricky material, because from one side you want the material to be liquid when you print it, but you want it to be solid when it’s done and coming out of the printer,” Schaal said. “So you have to combine a heating source on one side and deal with it. And of course people love chocolate, so it’s difficult and romantic for people.”

Lipton said the printer is also being used for medical purposes in animals and humans. The machine recently printed out an outer shell of a human ear and an eye lens, and the Cornell Veterinary Hospital is testing synthetic bones for dogs needing replacements.

“They’re doing one surgery now where we printed out a bone, and they’re trying to figure out if it’s strong enough to do a surgery,” Lipton said.

The team is also launching the FAB@School program, which aims to put models of these printers into classrooms around the country to let students use them firsthand. While they have not distributed the printers to schools yet, the idea is that students can access the printers as early as second grade and continue to use the software and machinery through high school to build better houses and machines for tomorrow.

Lipton said the 3-D printer is a perfect example of the power current technology has.

“I mean, we talk about how awesome science will be in the future,” Lipton said. “But look what you can do right now.”