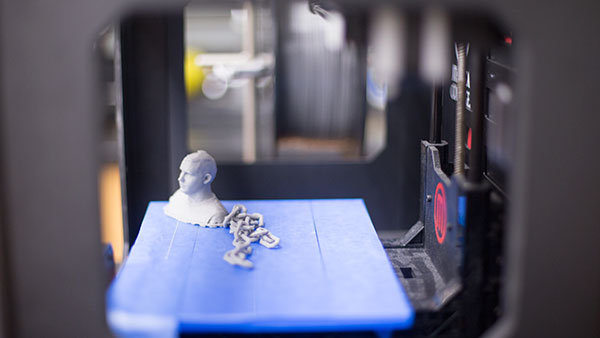

With everyday advances in technology, new resources are becoming increasingly available to students. As a working example of this, Ithaca College joined the likes of neighboring Cornell University last December by purchasing its own 3-D printer.

Now, the college’s printer is being used for architectural conservation and archaeological analysis. Both are projects with which students are heavily involved.

There is also another printer on the way: On Sept. 5, Michael “Bodhi” Rogers, associated professor of physics and astronomy, was given approval to buy another 3-D printer. This second printer is both larger and more expensive, costing $6,500, he said.

The printer works through a process called additive manufacturing, which is a means of creating an object by adding material to it layer by layer based on a digital blueprint. However, it can also work in the opposite sense, where a solid block of plastic is placed in the printer and the object is carved out of it, similar to chipping away at a block of ice to make an ice sculpture.

Rogers purchased the printer currently in use, and he and his students are using it for a range of applications, one of which is a collaboration with the anthropology department. Aside from a doctorate in physics, Rogers also has a Master’s Degree in anthropology, and he said he often works at archaeology sites. His interest in the subject has resulted in him collaborating with Jennifer Muller, assistant professor of anthropology, to scan artifacts and other objects found at archaeological sites.

Muller is a forensic anthropologist who studies human remains to examine conditions such as diet, stresses and disease, she said. She is currently participating in a project examining remains from the Erie County Poorhouse in Buffalo, New York, from the 1800s.

Rogers said he and Muller pulled several of the bones and scanned them to see if the scanner can pick up the features needed by Muller to conduct her analysis.

Muller said the 3-D printer is highly useful in this instance because the bones Muller and Rogers are scanning need to be re-buried, and she is only permitted to keep them for a limited period of time. Scanning and printing the bones, she said, allows her to study them for as long as she likes while also being very respectful of the remains.

Muller said she believes this to also be a special advantage to students because while old, fragile artifacts cannot be handled, printed copies can be, and this allows students more hands-on learning.

“We can be as descriptive as possible on paper, but there’s nothing like having a replica of the human body,” Muller said.

Rogers said he and his students have also found use for the printer in terms of designing and printing their own parts that are required for their physics classroom equipment. This is especially useful regarding specialty parts that cannot be easily purchased, as well as parts to older instruments that cannot be replaced, he said.

Corinne Steffens, a junior in the School of Humanities and Sciences, was involved with this as she worked with Rogers on his research team. She said her responsibilities often entailed using the 3-D imaging program Google SketchUp to draw printable objects, such as screws, that could then be printed and used.

She said she had no familiarity with this program prior to the purchasing of the printer and is currently working to print a copy of one of the Towers residence halls that she drew using the program, but she is encountering difficulties with the actual printing.

Steffens said this has increased her problem-solving abilities by requiring her to combine creativity and functionality.

“I know what I want, but it doesn’t function right, so I have to be creative to figure out a way to make it work, and that’s all what science is about,” Steffens said.

Rogers said he is also utilizing the printer with his research team in the scanning of historic structures with a $95,000 laser scanner, the funds for which were acquired through the normal college budgeting process.

Laser scanning provides a digital copy of the structure so that in case it is ever damaged, the readings will allow for it to be reconstructed, as well as for analysis of the structure in a different format, Rogers said. He said he is hoping to print out copies of old structures layer by layer so they may be studied from a new, handheld perspective, as he and his team are working to shrink these very large scans to small 3-D copies.

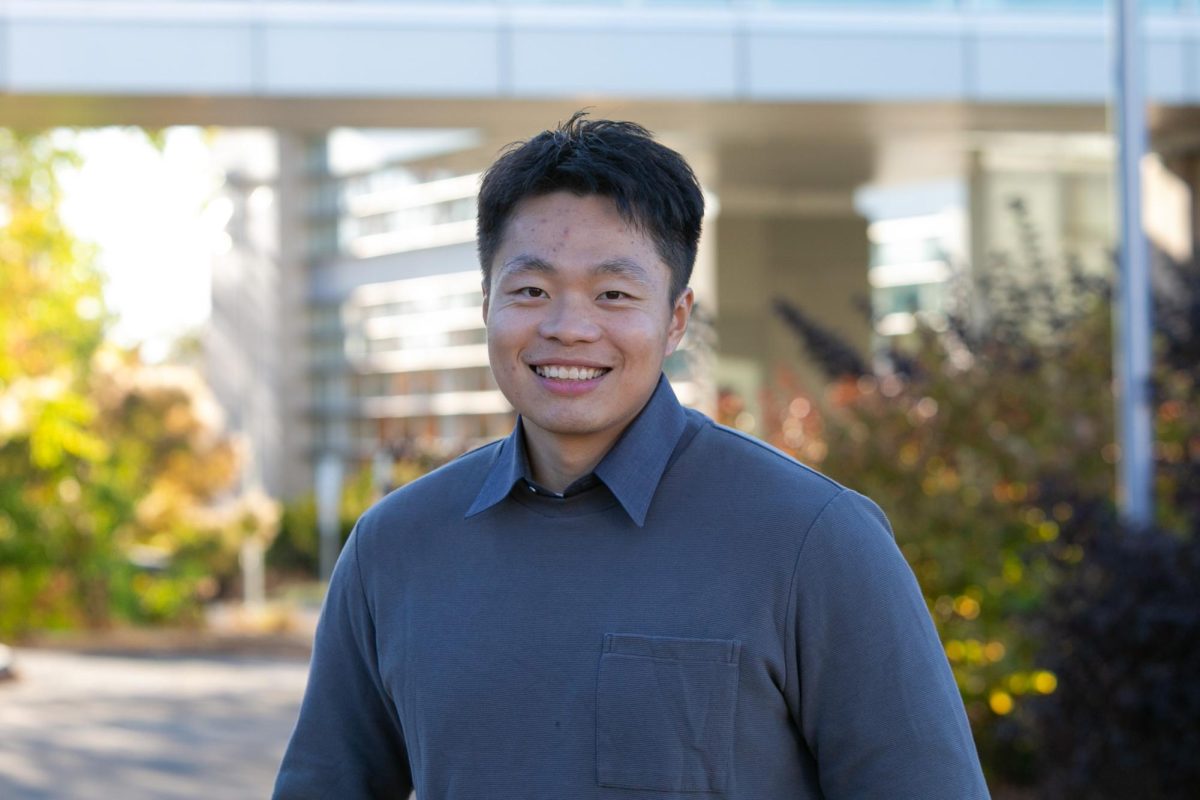

Evan Van de Wall, a junior physics major, is part of the team working on converting 3-D laser scans of historic buildings into printable objects.

In his research, Van de Wall said, he has come to appreciate the advantageousness of the printer when it comes to architectural conservation. In addition to this, he said the school has found another important use for the printer in relation to investigating crime scenes.

“A crime happens, you send in a person with a scanner, he sets it up, he scans the whole room, everything is now in place, measurable,” he said.

Van de Wall said since the digital scans show different levels of absorption, residue such as blood on walls would be made more apparent, thus allowing for a more thorough analysis.

When the printer was first purchased, the research team gave its contact information to the Ithaca Police Department in case the scanner would ever be required, but Van de Wall said they have yet to receive any kind of call.

Van de Wall said he is excited about obtaining a second 3-D printer, as it provides more opportunities to connect the disciplines as well as invaluable classroom experience.

“I don’t know many other friends of mine that get this type of hands-on experience,” Van de Wall said.