Over the summer, the School of Humanities and Sciences added a third 3-D printer to its existing fleet. The new printer and its accompanying scanner will allow students and staff members across a wide academic spectrum easier access to 3-D replication equipment.

Ithaca College acquired its first 3-D printer — a MakerBot Replicator 2 — in December 2013, which was later joined by a larger MakerBot Replicator Z18 printer in Fall 2014. Michael “Bodhi” Rogers, professor in the Department of Physics and Astronomy, is responsible for securing the funding for the latest printer on campus. The new scanner and printer were approved through this year’s budget request by H&S, and each costs about $3,000, Rogers said.

The newest printer is largely the same as the one purchased in 2013, but it will be given its own laboratory in an effort to make the technology more accessible to students and faculty. Pairing printers to 3-D scanners allows Rogers and his colleagues to replicate and create high-definition copies of anything from castles to clavicles.

While printers transform computerized files into tangible objects, scanners work on the opposite side of the process — converting physical things into data that can then be stored as a file and later printed. H&S has two kinds of scanners. One type works for larger objects and is primarily used for architecture-related projects. The other, smaller scanners can take scans of objects like bones, making them useful for a different set of applications.

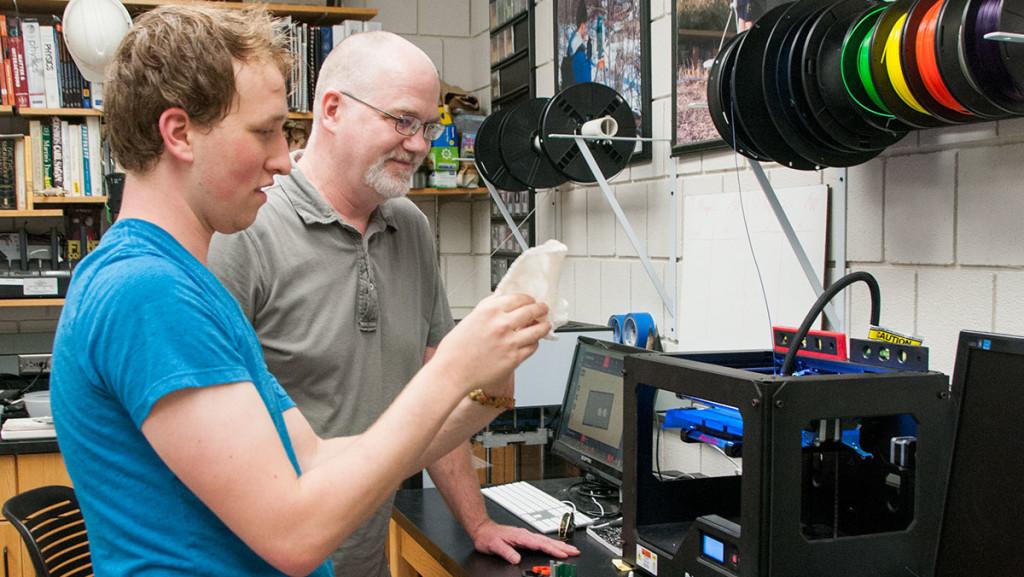

Senior physics major Benjamin Bouricius is currently working on a project that uses 3-D–printing technology to construct a prosthetic hand.

“I found a group called e-NABLE, and they have open-source designs for prosthetic limbs,” Bouricius said. “I got the design online for free, and then because I have access to a printer, I made one, and the next step is to send this off to them. If they think it was done well enough … I’ll be added to a list, and anyone in the area who needs prosthetics might be sent my way.”

Bouricius said he is currently in the process of fine-tuning the design. In addition to prosthetics, he said he believes 3-D printing has great potential in the medical field at large.

Bouricius has also continued work on another, simpler project using the 3-D printer to create Ithaca College–themed merchandise, including products such as a miniature Textor Ball and small-scale East Tower. He said such items could be sold in the Bookstore, though currently they are not available for sale.

Rogers is also currently looking into requesting the purchase of a second, more modern architecture scanner to supplement the existing one, purchased three years ago. A great cost of scanning a building is incurred from hotel and meal expenditures associated with staying on site, Rogers said. Thus, he said, a newer, faster scanner would save time and money spent while scanning buildings.

“The [old] scanner … takes a reading 50,000 times per second. The new one does it 1 million times per second,” Rogers said. “That can really make a big difference on the types of projects we can do.”

If successful, the acquisition of a faster scanner would also help Rogers perform a complete scan of Trim Castle, one of the largest and best-preserved Norman castles in Ireland. Rogers said he is finalizing approvals on the project and plans to travel with a team of students — and the 3-D scanners — to the castle next summer.

David Salomon, assistant professor of art history and coordinator of architectural studies at the college, has used an existing 3-D printer with students for projects in their architectural design class.

Salomon said his students made designs using AutoCAD and SketchUp, which were then converted to 3-D models using the printer. The finished products included models of buildings like a New York City apartment complex and an art gallery for campus.

“It’s a great resource to have,” Salomon said. “We look forward to using it more in the future.”